Insulator ------ Bugs?

by Larry Larned

Reprinted from "INSULATORS - Crown Jewels of the Wire", December 1977, page 13

The transcontinental telephone toll line was constructed by American

Telephone & Telegraph Company in 1915. The line was constructed from New

York to San Francisco and routed through Trenton, Pittsburgh, Chicago, Des

Moines, Omaha, Denver, Cheyenne, Salt Lake City, and Sacramento.

Open wire type

construction was utilized with No. 8 B. W. gauge copper .165 inches in diameter.

There were 130,000 poles used in the line, many of them carrying no wires except

the four wires making up the three transcontinental circuits spanning a distance

of 3,400 miles. The line consisted of two physical circuits and one phantom

circuit.

Prior to 1915 a toll line 3,400 miles long was not possible without

technological improvements in telephone engineering. In the words of ATT's

President, Theodore N. Vail, "It is the cumulative effect of improvements,

great and small, in telephone, transmitter, line cable, switchboard, and every

other piece of apparatus or plant required in the transmission of speech"

that made the long distance service possible.

One of the improvements which Mr.

Vail referred to was the development of the loading coil. It was found that the

efficiency of long telephone circuits could be increased by inserting inductance

coils in the circuit at suitable distances. The coils consisted of a core,

shaped like a ring, made up of very fine, carefully insulated, iron wires .004

of an inch in diameter. Around this iron core are wound two copper wires, one

for each side of the telephone circuit. These windings of copper wire are so

placed that when in service each will magnetize the core in the same direction,

so the mutual induction will be added to the self induction. The coils were

placed in suitable iron cases and mounted on the cross arms along the line.

However, it was soon found that the problem of loading No. 8 circuits was

largely one of insulation. Low insulation on a loaded circuit has a much greater

effect upon the efficiency of the circuit than has low insulation on an unloaded

circuit. As the efficiency of the circuit is increased, the more serious becomes

the insulation problem. The loading coils were connected to the open wire

circuits with rubber-covered bridle wire. The leakage over the braid of the

bridle wire turned out to be a serious problem; and to solve it, special

insulators, called bridle insulators, through which the bridle wire passed, were developed. (See pages 20 - 21 of February 1977

Crown Jewels.) The bridle insulator, however, did not completely solve the problem of

insulation on the loaded circuits. Each circuit on the transcontinental line

employed more than 250,000 pin type insulators, and considering the leakage at

each insulator during wet weather, it was evident that the cumulative effect of

any improvement in the insulation at each insulator would be of great help.

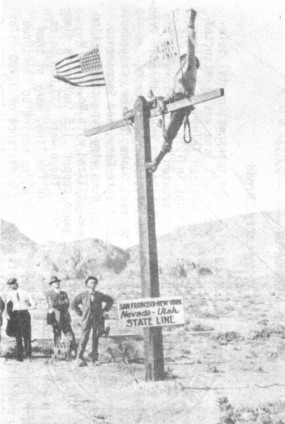

Final pole of the Transcontinental Line.

(Courtesy AT&T)

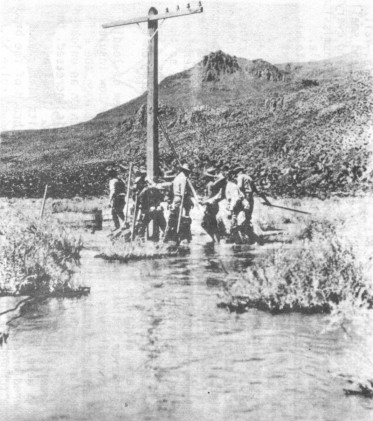

Construction of the Transcontinental Line through Nevada 1914.

(Courtesy AT&T)

Therefore, a new type of double petticoated porcelain insulator was designed and

placed on the line. However, it was not too long after the line was placed in

service, that strange events took place which puzzled engineers and defied the

laws of electrical science and the conclusion of laboratory experiments. The

porcelain insulators became infested with bugs - what species of bug I don't

know, and Bell System officials won't divulge. However, the opacity of the

porcelain and the shelter provided by the double petticoat skirt caused the bugs

to home in on the line and to propagate more bugs. The Bell System, not wishing

to employ the people necessary to station a flit gunner at each pole, decided to

remove all of the porcelain insulators and replace them with glass insulators.

During 1918 the job was accomplished, the bugs lost their home, and once again

the technology of man prevailed.

An interesting question concerning the

transcontinental line is, what type of porcelain insulator was developed, and

what type of glass insulator replaced it. AT&T has found no record for the

development and purchase of 500,000 porcelain insulators, nor the purchase of

500,000 glass replacements. I can speculate, however, with the assistance of

Jack Tod, that the porcelain was most probably U-177. Three photographs of the

line strongly suggest U-177. This insulator was made by Locke and cataloged for

general distribution in 1916 as #3188. Its replacement was, in all probability,

CD 152, the style in general use during this era for communications work. Of

course as time, went on, the CD 154 was developed with its larger capacity wire

groove. The CD 154 was first produced in 1922 and became the standard long

distance insulator for the Bell System.

Perhaps some of CJ's readers who live

near the original route of the line and have found relics from it, could describe their goodies and verify the legacy which

photographs appear to describe.

|